MIL-PRF-49368C (CR)

4.

VERIFICATION

4.1

Classification of inspection.

Inspection shall be classified as

follows:

a. First article testing (4.2).

b. Conformance inspection (4.3).

4.2 First article testing. When specified in the contract or purchase

order (see 6.2.f) first article testing shall be performed by the contractor.

The quantity of initial production test samples shall be as specified in the

contract or purchase order (see 6.2.b).

4.2.1 FAT Testing. Each eyepiece assembly in the FAT lot shall be

subjected to the inspections of Table I. Samples selected from the lot shall

be subjected to the inspections of Table II. Sample size shall be as

specified in the contract or purchase order (see 6.2.b). Failure of any

inspection shall be cause for rejection of that eyepiece assembly and may be

cause for rejection of the FAT. Inspections may be performed in any order

except for Immersion, which shall follow temperature extremes and temperature

shock.

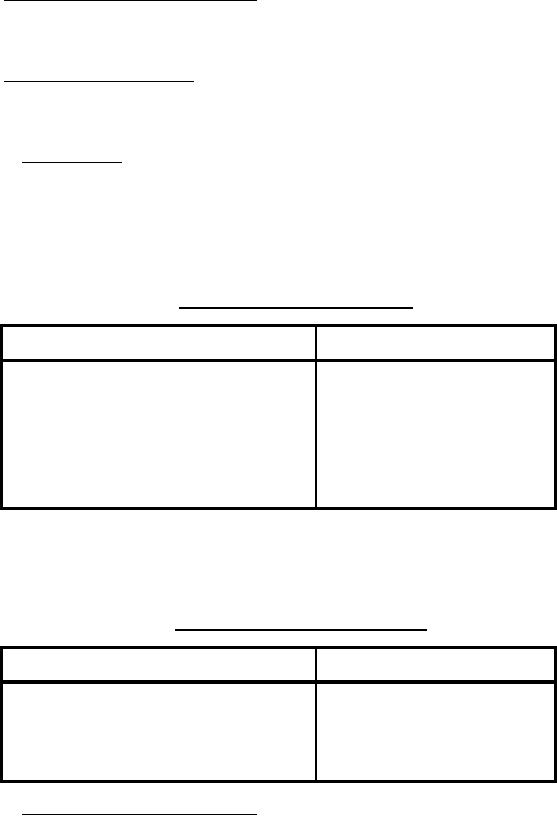

Table I Unit first article testing.

Requirement

Inspection

Paragraph

Effective focal length

3.6.1

Flange focal length

3.6.2

3.6.3

Field curvature

Linear distortion

3.6.4

Exit pupil

3.6.5

Transmission

3.6.6

3.6.7

Resolution

Diopter adjustment

3.6.8

Diopter range

3.6.9

Table II Sample first article testing.

Requirement

Inspection

Paragraph

Temperature Extremes

3.7.1

Vibration

3.7.2

Altitude

3.7.3

Humidity

3.7.4

Immersion

3.7.5

High intensity shock

3.7.6

4.2.1 Disposition of FAT samples. Disposition of FAT samples shall be

as specified in the contract or purchase order (see 6.2.b).

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business